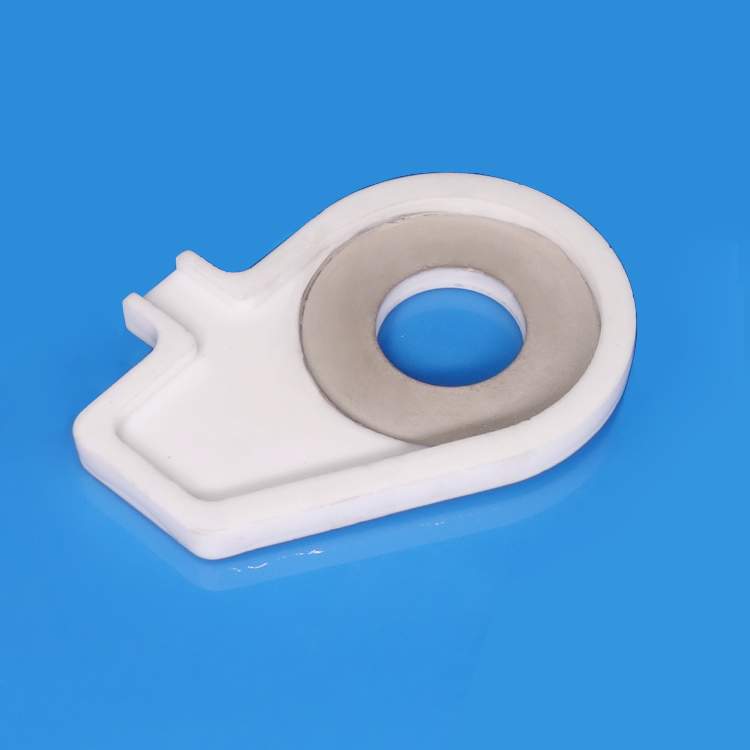

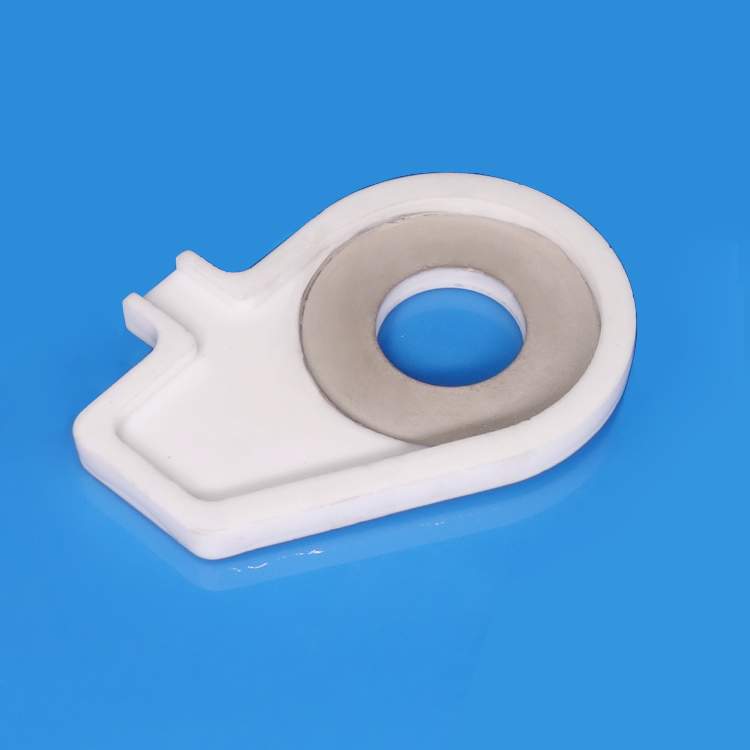

High Bonding Strength Metalized Ceramic Insulator for High Currency

Feedthru

Many technologies have been used to join ceramics to metals, or

ceramics to ceramics. Brazing is a desirable method for joining process because of its capability for

joining dissimilar materials, high reliability and precision production tolerance.

To join ceramics to itself or to metal, the critical problem is the

poor wettability of ceramics by filler alloys. When a metal layer

applied on a certain surface of ceramic parts, it will help to fix

the poor wettability well. That's why metalized ceramics play a

very important role between ceramics to ceramics, ceramics to

metals joining technology.

We manufacturer a variety of ceramic metalization components with

different materials, different designs, different specifications.

Many amazing solutions were to be supplied to our customers to

reach their toughest technical challenges.

Technical specification and production capability:

Optional material | 95% alumina | 99% alumina | Zirconium Oxide | Beryllia Oxide | Nitride Aluminum |

Max. outer diameter | 800 mm | Max. Inner diameter | 780 mm | Max. length | 1000 mm |

Nominal tolerance | OD ±0.05 mm | Nominal tolerance | ID ± 0.10 mm | Nominal tolerance | L ±0.50 mm |

Nominal flatness | 0.05 mm | Nominal roundness | 0.10 mm | Nominal parallelism | 0.05 mm |

Surface treatment | Metalization | Glaze | Polishing |

|

|

Metalization types | Ceramic base + Mo/Mn | Ceramic base + Ag plating | Ceramic body +Mo/Mn + Ni plating | Ceramic body + W + Au plating |

Prime features:

● High bonding/brazing strength ● Min. electric resistance and

vacuum tightness

● High mechanical strength, insulation strength ● Anti-chemical,

anti-aging without corrosion

● Super wear resistance with long service life

Key performance parameters

Leak rate | ≤1×10-11 Pa•m3 / s | Metal layer tensile strength | ≥ 150Mpa |

Volume resistivity

| ≥108Ω•cm

| CTE

| (6.5 ~ 8.0) × 10-6 /°C

|

Insulation strength

| ≥18kV/mm (D•C)

| Dielectric constant

| 9~10(1MHz, 20°C)

|

Visual quality: 1. No cracks, no bubbles; 2. Evenly distributed glaze; 3. No

contamination

|

Typical application of metalized ceramic components

Metallized ceramic insulators are widely used in electronics,

high-vacuum technology, sensors, and medical fields, like vacuum

interrupters, electron tubes, feedthroughs, medical linear

accelerators/ power tubes, photomultipliers, X-ray tubes, and

pressure sensors.

Packaging proposal and transportation

1. Vacuum packaging with drier as the inner package; 2. An exported

carton as the outer package; 3. The wooden case will be used if

needed.

Why choose us?

★ 10+ Years of manufacturing experience in OEM, ODM ★ Powerful R&D,

mass production capability

★ In-house comprehensive manufacturing types of equipment ★

Rigorous quality control system and processes

★ Surpassing pre-sales and after-sales service ★ Abide all orders

as the first priority

FAQs (Frequently Asked Questions)

Q1. Are you a factory or trading company?

A: We are a manufacturer. You are welcome to visit our factory.

Q2: Do you send a sample to check?

A: Sure, the sample is free and freight collect.

Q3: When will you ship it?

A: If the products are in storage, we'll ship within 48 hours

Q4: When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry. If

you are in urgent need of getting the price.

Please call us or tell us in your email so that we will proceed

with your inquiry as a priority.

Q5: Is it available to provide customized products?

A: We always support custom-made demand as per different materials,

dimensions, and designs.

Q6: How to ensure quality?

A: The dimension out of any batch will be carried out sampling

inspection per international AQL standard. A 100% cosmetic

inspection will be done.

Q7: What other products are you dealing with?

A: We focus on a variety of ceramic tubes, ceramic substrates,

ceramic sheets, textile ceramics besides metalized ceramics.