Industrial High Hardness Precision 95% 99% 99.5% Al2O3 High Alumina

Bush

Main characteristics of alumina ceramic bush

1. Outstanding wear resistance, over 276 times in comparison with

stainless steel

2. Great mechanical properties, hardness, compressive and flexural

strength are much higher stainless steel

3. Exceptional corrosion resistance, it can withstand various

strong acid and alkali, like HF, H2SO4

4. Extraordinary electrical insulation, it always us in many high

voltage, high-current application

Specification of the ceramic bush

1. Material options: different purity alumina (from 95% to 99.8%),

zirconia, Silicon carbide, steatite

2. Forming methods: Extrusion, Dry pressed, Hot pressed, Ceramic

Injection molding, ISO pressed

3. Dimension capability: Min. the inner diameter can be 1mm, Max.

the outer diameter can be 800mm

4. Tolerance: outer diameter can be 0.005mm, the inner diameter can

be 0.01mm, the overall length can be 0.01mm

5. Surface treatment: External and internal surface to be polished,

glazed or metallized

6. Secondary processing: CNC machining, lapping, grinding,

precision cutting and so on

Description of ceramic alumina bush

Aluminum Oxide (Alumina, Al2O3) is the most extensively used

advanced ceramic material due to their outstanding property

characteristics and cost-effective advantage. As with the purity

increases, both wear resistance and corrosion resistance also

increases, so alumina are grouped together based on purity levels,

including 75% alumina, 85% alumina, 90% alumina, 95% alumina, 99%

alumina, 99.5% alumina, 99.8% alumina, 99.9% alumina.

Alumina ceramic tubes generally used as a kind of standard

protection part, so our facility has many selections of stocks. Our

vast, readily-available inventory allows us to supply our

customer’s ceramic tube needs immediately, even for hard-to-find or

specialty products. Aluminas are used in a variety of

general-purpose applications, and their grade is chosen based on

the application environment. Additionally, different purity alumina

can be formulated in our factory if needed for more demand

applications

Material Data. Sheet

| General | Property | Units | 99.5% alumina | 99% alumina | 95% alumina |

| Mechanical | Density | g/cm3 | ≥3.85 | ≥3.80 | ≥3.60 |

| Water absorption | % | 0 | 0 | 0 |

| Hardness | HV | 1700 | 1700 | 1500 |

| Flexural strength | Mpa | ≥379 | ≥338 | ≥320 |

| Compressive strength | Mpa | ≥2240 | ≥2240 | ≥2000 |

| Fracture toughness | Mpa m 1/2 | 4-5 | 4-5 | 3-4 |

| Thermal | Max. service

temperature

(Non-loading) | ℃ | 1650 | 1600 | 1450 |

| CTE (20-800℃) | 1×10 -6 /℃ | 6.5~8.0 | 6.2~8.0 | 5.0~8.0 |

| Thermal shock | T(℃) | ≥250 | ≥200 | ≥220 |

| Thermal conductivity (25℃ ) | W/m.k | 30 | 29 | 24 |

| Specific heat | 1 x 10 3 J/(kg·K) | 0.78 | 0.78 | 0.78 |

| Electrical | Volume resistivity (25℃ ) | ohm.cm | >1 x 10 14 | >1 x 10 14 | >1 x 10 14 |

| Insulation strength | KV/mm | 19 | 18 | 18 |

| Dielectric constant (1Mhz) | (E) | 9.7 | 9.5 | 9.5 |

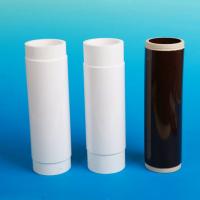

Picture gallery of ceramic tubes

We also produce lots of different types of ceramic tubes, including

threaded tube, half tube, one end tubes and so on.

Packaging proposal & Transportation methods

1. Vacuum packing with desiccant as an inner package;

2. Then, exported carton as an outer package.

3. Finally, it will be packed with a wooden case if needed.

4. We regularly use DHL, UPS, FedEx, and TNT to ship small parcels.

5. For large volume order, we could ship it by sea as per

customers' needs.

FAQs (Frequently Asked Questions)

Q1: Is it available to produce customized products?

A: We always support custom-made metallic coated ceramic insulators

as per different dimensions, designs, metallization, and platings.

Q2. When can I get the price?

A: We regularly quote within 24 hours after we get your inquiry. If

you are in urgent need of getting the price, please call us or tell

us in your email so that we will proceed with your inquiry as a

priority.

Q3. How long can I expect to get the sample?

A: After you pay the sample charge and send us confirmed files, the

samples will be ready for delivery in 4 weeks. The samples will be

sent to you via express and arrive in 3-5 workdays. You can use

your own express account or prepay us if you do not have an

account.

Q4. How long does the whole procedure being worked out?

A: After you place an order, the manufacturing time is about 25

working days.

Q5. How to ensure quality?

A: The dimension out of any batch will be carried out sampling

inspection per International AQL standard. A 100% cosmetic

inspection will be done.

Q6. Are you a factory or trading company?

A: We are a professional manufacturer. We are warmly welcome

clients from worldwide to visit our factory and cooperate with us.